Research

ResearchWe focus on new approaches to designing and constructing MEMS-based sensors that offer high sensitivity, mechanical/chemical/thermal robustness, biocompatibility, cost effectiveness, and other important features achieved through the use of a variety of functional materials and the development of novel microfabrication processes for them.

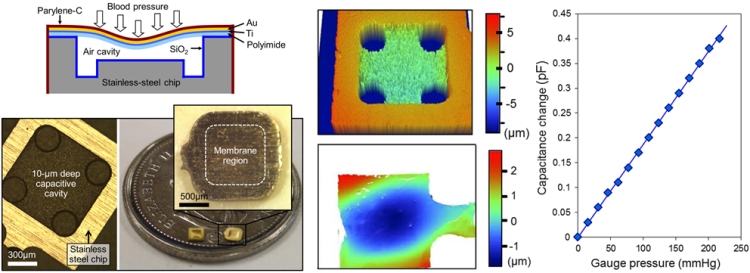

This study has focused on a new microfabcricaiton approach that enables rapid manufacturing of micro capacitive pressure sensors, with inherent biocompatibility so that the device does not require additional packaging components for in-vivo applications. The sensor chip was constructed by thermal bonding of a Parylene-metal multilayer membrane onto a micromachined medical-grade stainless-steel chip with a capacitive cavity, eliminating lithographic processing from the sensor fabrication to achieve rapid and low-cost production. All the structural materials used were biocompatible for the chip to be implantable. A highly linear pressure response was verified. This novel sensor has played a core role in our development of "smart" stents (refer to Medical MEMS) and offers broader application opportunities in biomedical and other areas.

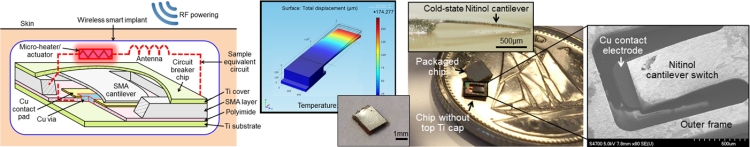

We have developed a novel MEMS circuit breaker for thermal management of biomedical microsystems specifically targeting at implant applications. The circuit breaker was micromachined to have a shape-memory-alloy cantilever actuator as a normally closed temperature-sensitive "smart"' switch to protect the device of interest from overheating, a critical safety feature for intelligent implants with embedded actuators including those that are electrothermally driven. The breaker was microfabricated using biocompatible materials with a chip-based titanium package. The chip is operates in a fully passive manner that removes the need for active sensor and circuitry to achieve temperature regulation in a target device, contributing to the miniaturization of biomedical/implantable microsystems where thermal management is essential.

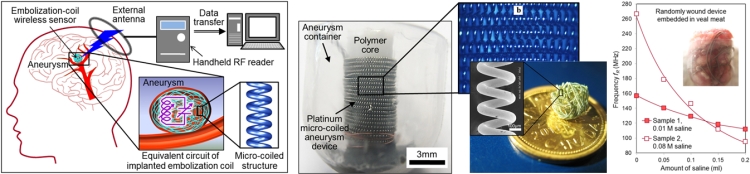

The rupture of a cerebral aneurysm is the most common cause of subarachnoid hemorrhage. Endovascular embolization of aneurysms by implantation of Guglielmi detachable coils (GDC) is a major treatment approach to the prevention of a rupture. Implantation of GDC induces formation of tissues over the coils, embolizing the aneurysm and blocking blood entry. However, a failure of this process often occurs. The existing diagnostic methods are not only ineffective for continuous monitoring of the lesion but also require extremely expensive equipment. To address these issues, we have proposed the first technique for wireless monitoring of aneurysm embolization, in which implanted coils are used as RF resonant sensors for blood entry. Experiments showed that commonly used GDCs could function as such wireless sensors. The wireless detection of the resonance of platinum GDC-like coils embedded in aneurysm models and tracking the entry of saline into the models via frequency monitoring were successfully demonstrated. This outcome opens up new horizons that could enable long-term, noninvasive, and cost-effective remote monitoring of cerebral aneurysms treated with embolization coils.

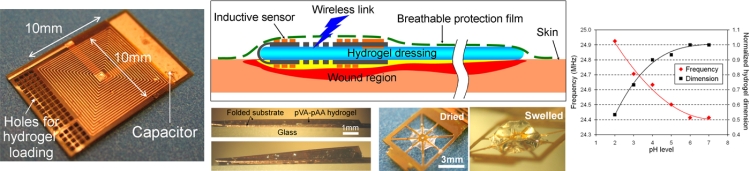

This project investigated a novel inductive transducer and produced battery-less wireless sensors based on the transducer for bio/chemical sensing applications. The sensors were fabricated using the flex-circuit technology in combination with responsive hydrogels. The inductive transducer has a folded dual-spiral coil microfabricated on flexible polymer substrate that sandwiches the hydrogel element. This fold-and-sandwich construction allows incorporation of a variety of functional hydrogels, offering a wide range of potential applications. Wireless pH sensing was demonstrated using pH-sensitive poly(vinyl alcohol)-poly(acrylic acid) hydrogel coupled with the transducer, toward the application to wireless tracking of wound healing process in which the pH level of wound fluid is sensed as an indicator of wound condition.

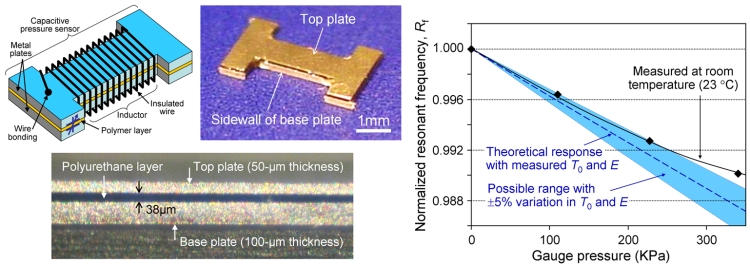

A novel capacitive pressure sensor has been developed using a combination of micromachined stainless-steel electrodes and an intermediate soft-elastomer layer. This new sensor is constructed without thin-film diaphragms and cavities used in typical MEMS capacitive pressure sensors to achieve very high mechanical robustness. The sensor is also chemically inert. Wireless pressure sensing was demonstrated using fabricated prototypes. With its mechanically and chemically robust construction, the device offers unique opportunities in harsh-environment applications in which conventional MEMS pressure sensors pose reliability issues.

Collaborator: Prof. Yogesh Gianchandani, University of Michigan Ann Arbor, USA

Jump to other research theme:

The main page of Research