Research

ResearchCarbon nanotubes (CNTs) have been attracting extensive interest due to their exceptional properties in different domains. Arrays of vertically aligned CNTs so called CNT forests offer unique characteristics not available with disordered CNTs. The CNT forest may be viewed as a new type of functional bulk material that can be harvested for numerous applications in MEMS, sensors, energy storage, heat management and other important areas. To this end, we are investigating methods and techniques for post-growth processing of this promising material, which will be critically important for it to be fully leveraged for different applications. We are also exploring revolutionary applications of the CNT forest, aiming to establish knwoledge and technology base for the design and production of next generation devices uniquely enabled by the material.

Collaborator: Prof. Alireza Nojeh, ECE department, UBC

Process

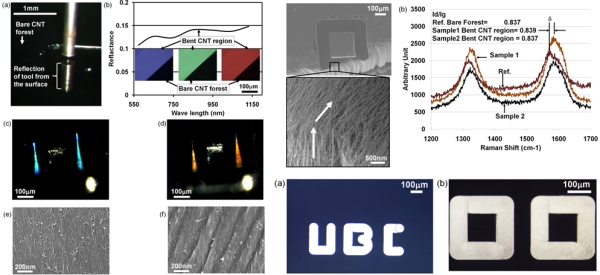

To acqire freedom in designing devices based on CNT forests, it is essential to acquire an ability to create free-form micro/nanostructures of the material with high precision. This is difficult to achieve with their synthesis process, chemical vapor deposition, as it only provides 2-dimensional-like structures with uniform heights, and thus post-growth processing will be an important path to fulfilling the need. Our study has shown that dry µEDM is a very promising method for such processing. It has revealed that the removal mechanism in this process may be fundamentally different from that in typical µEDM based on direct melting/evaporation of sample material and that oxygen plays a vital role for successful patterning process. We have also found a favorable scaling effect of the electrode on removal effect of discharge and exploited it to show the feasibility of nano-EDM of the material.

As an extended work toward utilizing the process for product manufacturing with high throughput, we have developed planar microelectrode arrays created through a UV-LIGA process and demonstrated batch-mode micropatterning of CNT forest using the array. Elemental and molecular analyses showed no sign of significant crystalline deterioration or contamination in the nanotubes processed with theses discharge techniques.

CNT forests are known to be among the darkest materials on earth - they absorb the entire visible range of electromagnetic wave more efficiently than any other known black material. We have discovered that controlled mechanical processing of the CNTs produces mirror-like reflective surfaces on the forest, with a reflectivity higher than a typical level of pure forests by over two orders of magnitude for a wide range of spectrum. Direct patterning of micromirrors in the forest was demonstrated to show its potential application for producing monolithically integrated reflector-absorber arrays in the material.

Application

Reliability and lifetime of the contact are among the challenges of MEMS contact switches. Because of its large surface area and promising electrical, mechanical, and thermal properties, the CNT forest is a good candidate for a more reliable contact material for the devices. To verify this potential, we have prototyped normally-open MEMS switches with CNT forests integrated as their contact material. Shape-memory-alloy (SMA) cantilevers were thermally actuated to perform switching in them. These SMA actuators provided high forces to enable distributed contacts with the CNTs, achieving low contact resistances and high ON/OFF resistance ratios. To enhance the contact area/conductance of the switch, the CNT forest was dry µEDMed to have a tapered contact surface. We showed high-power switching with over 5 W input powers and long-term operation for ~1.4 million switching cycles with the prototypes. The results suggest that a combination of CNT contact and SMA actuator is a promising path to realizing reliable MEMS contact switches for high-power, DC/low-frequency applications, and that post-growth 3-D shaping of the forest contact is highly effective to maximize the contact performance.

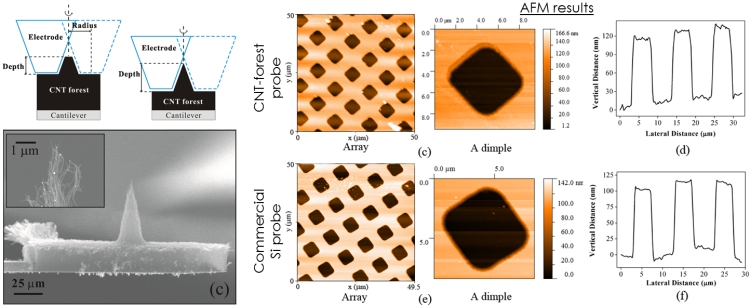

We have developed a scanning microscopy probe based on 3-D shaped CNT forest and demonstrated its performance in atomic force microscopy (AFM). Micro-scale CNT forests directly grown on Si cantilevers were patterned into cone shapes with the tips of a few individual nanotubes. This cone-shaped CNT-forest probe offers significantly higher mechanical stability/robustness than the common single-CNT probes. The patterning process also improves the uniformity of the CNT forests grown on each cantilever. These features have been brought by the unique ability of post-growth free-form micropatterning of the material.

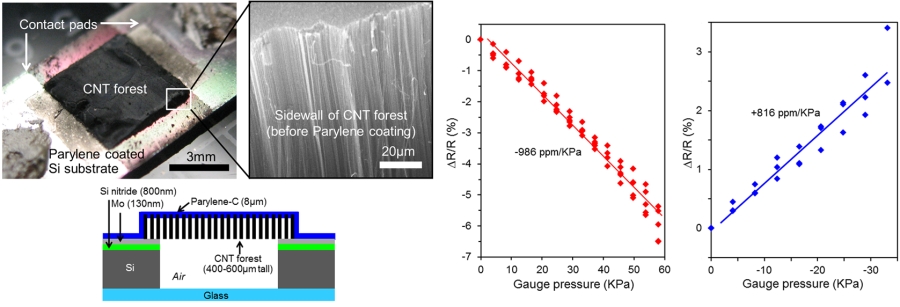

CNT forests exhibit piezoresistivity along their lateral directions. The spatial change in CNTs, induced by a stress applied to them, can increase or decrease the number of junctions between the entangled CNTs in the forest, leading to a collective change in its lateral electrical resistance. This unique piezo feature offers a wide range of sensor applications. This project is aimed to study CNT-forest-based sensors implemented though MEMS approaches. We have developed a pressure sensor, in which a CNT forest is supported by a movable suspended polymer membrane, providing nearly symmetric responses to both positive and negative gauge pressures with good linearity. This effort has also led to a novel CNT-forest strain sensor that provides much higher sensitivity in the strain range than those reported for other types of CNT-forest/polymer composite piezoresistors.

Jump to other research theme:

The main page of Research