Tissaphern Mirfakhrai

Thermomechnical Reliabilty of Multilayer Ultra-Barrier Films (UBF) and Encapsulants for Solar Cells and OLEDs

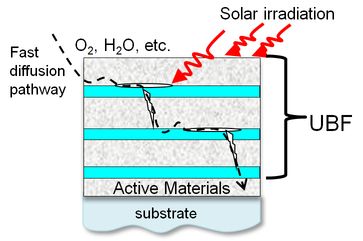

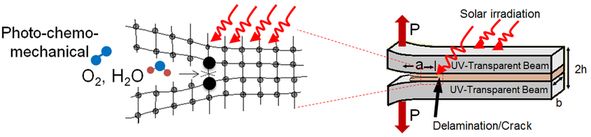

Barrier Films and encapsulants for photovoltaic technologies are exposed to some of the most severe operating conditions involving thermal cycling, moisture and chemically active species present in the environment. These multilayers are also exposed to solar radiation, where higher energy UV photons are known to cause serious damage. Although frequently reported, virtually nothing is known regarding the fundamental degradation processes that lead to loss of adhesion, debonding of interfaces, and cracking of nanostructured layers that happen in the barrier and encapsulation layers. By providing fast diffusion pathways for water vapor and oxygen, these processes speed up the breaking of conjugation in the active materials, as well as delamination and oxidation of metal electrodes, leading to decreased device efficiency and ultimately loss of device function (Figure 1).

Despite extremely optimistic forecasts for low cost and efficient photovoltaic technologies, device reliability and lifetimes may present overwhelming barriers for the success of these promising and environmentally sound new technologies. We are conducting the first quantitative characterization of the synergistic effect of mechanical stresses, environmental species like moisture and oxygen, and importantly, UV radiation, on degradation processes in thin films and coatings. These results are obtained in a newly designed in-situ testing system that allows us to characterize defect evolution and associated molecular bond rupture kinetics in barrier films (Figure 2). A variety of coatings, encapsulants and barrier layers will be investigated with this technology.

An important aspect of the research will be to develop mechanistic models to describe the kinetics of interfacial defect evolution under UV irradiation conditions in these barriers. Our modeling activities will be closely linked to our experimental work to provide experimental calibration and input to our models. We will use chemical reaction rate and atomistic models involving a range of kinetic parameters to rationalize the effects of materials chemistry, environmental species, and UV photon energy and flux on the kinetics of debond evolution.

Creation of fast diffusion pathways in UBFs leads to degradation of the active materials

Schematic diagram of setup for subcritical fracture test of barrier film with in situ UV exposure